Solid CCS tech invented

New decarbonisation tech can instantly convert CO2 to solid carbon.

New decarbonisation tech can instantly convert CO2 to solid carbon.

Australian researchers have developed a new method to help advance the decarbonisation of heavy industries.

The technology from researchers at RMIT University is designed to be smoothly integrated into existing industrial processes.

Decarbonisation is an immense technical challenge for heavy industries like cement and steel, which are not only energy-intensive but also directly emit CO2 as part of the production process.

The new technology offers a pathway for instantly converting carbon dioxide as it is produced and locking it permanently in a solid state, keeping CO2 out of the atmosphere.

Researcher A/Prof Torben Daeneke said the work builds on an earlier experimental approach that used liquid metals as a catalyst.

“Our new method still harnesses the power of liquid metals but the design has been modified for smoother integration into standard industrial processes,” Dr Daeneke said.

“As well as being simpler to scale up, the new tech is radically more efficient and can break down CO2 to carbon in an instant.

“We hope this could be a significant new tool in the push towards decarbonisation, to help industries and governments deliver on their climate commitments and bring us radically closer to net zero.”

Technologies for carbon capture and storage (CCS) have largely focused on compressing the gas into a liquid and injecting it underground, but this comes with significant engineering challenges and environmental concerns. CCS has also drawn criticism for being too expensive and energy-intensive for widespread use.

Dr Daeneke says the new approach offers a sustainable alternative, with the aim of both preventing CO2 emissions and delivering value-added reutilisation of carbon.

“Turning CO2 into a solid avoids potential issues of leakage and locks it away securely and indefinitely,” he said.

“And because our process does not use very high temperatures, it would be feasible to power the reaction with renewable energy.”

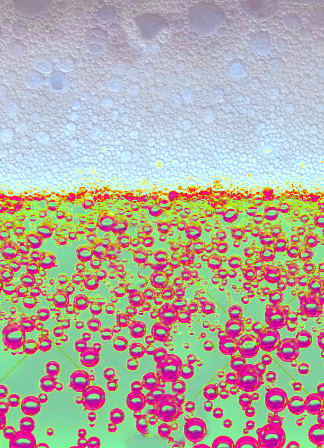

The “bubble column” method starts with liquid metal being heated to about 100-120C.

Carbon dioxide is injected into the liquid metal, with the gas bubbles rising up just like bubbles in a champagne glass.

As the bubbles move through the liquid metal, the gas molecule splits up to form flakes of solid carbon, with the reaction taking just a split second.

“It’s the extraordinary speed of the chemical reaction we have achieved that makes our technology commercially viable, where so many alternative approaches have struggled,” says co-lead researcher Dr Ken Chiang.

The next stage in the research is scaling up the proof-of-concept to a modularized prototype the size of a shipping container, in collaboration with industry partner ABR.

A provisional patent application has been filed for the technology and researchers have recently signed a AU$2.6 million agreement with Australian environmental technology company ABR, who are commercialising technologies to decarbonise the cement and steel manufacturing industries.

The team says it is keen to hear from other companies to understand the challenges in difficult-to-decarbonise industries and identify other potential applications of the technology.

Print

Print